Just curious, what you mean by the non-locking knives. Is the Victorinox folding grafting knife like the ones below, not ‘locking’? I have some more expensive knives but maybe like the Victorinox the most.

Some of the more expensive ones kinda scare me when folding them back in. Those are sharp and retract so fast that I’m careful when folding them back in to make sure my fingers aren’t anywhere near there. The Victorinox springs back as well but feels a bit more ‘looser’/playful so i can retract it and guide it in a bit be4 it springs back completely.

That is exactly what I am talking about. I do not use folding knives without locks for anything.

gotcha, i think i found the locking type you mentioned that you like. So it has a special mechanism to lock/unlock:

Maybe I’ll grab at some point. Thanks for pointing it out.

I am still using this inexpensive knife… it sharpens well and gets the job done.

Lots of successful grafts with it last 2 springs.

Around 10 bucks…

Yes it does. It’s also chisel ground. Also, you can find it cheaper elsewhere. Should be around $25

Since have one of these what is the black piece right below the blade? Is that the blade lock?

Thanks for the added report! And that other one looks like a nice addition.

I was ready to pull the trigger on the Leonard knife, until I saw the shipping charge put it in the range of the Due Buoi knives. Ended up finding the stainless Due Buoi 202L for about $40 shipped on eBay, so I went with that. I’ll post my thoughts on that here after it arrives.

Got my Due Buoi knife today, and wow! This is a great knife. Was shaving sharp out of the package, and was still shaving sharp after about 15 test cuts on peach prunings. Not a very extreme stress test, but already doing way better than my makeshift grafting knife. The steel is N690, which is about as tough as 1095 but stainless and with much better edge retention. I wouldn’t be surprised if it lasted the whole season without needing any sharpening beyond a stropping or two.

The blade geometry is nice. Much wider and stiffer than what I’ve been using. The grip is a smidge thicker than I’d like, but I think I’ll get used to it pretty quickly.

While it’s a folder, it registers very firmly with the back spring. It feels almost as solid as a fixed blade knife. It doesn’t lock, but with the aforementioned firm seat on the spring, it won’t close on you unless you’re doing something ill-advised. I did put a couple drops of oil in, and it seemed to open/close more smoothly, but still firmly.

And did I mention it looks good, too? I selected one with wood scales. They come unfinished, so I put a beeswax/mineral oil blend on for some protection (you can see the difference in the pics where the wood is darker). The overall build quantity is good. I like the look of brass and wood. The logo is pretty cool, too, and is actually stamped into the blade.

I would definitely recommend this knife, especially at the price I paid ($40 shipped). I don’t have any experience with Tina knives, but I can’t imagine how they would be significantly better than this one

Looks somewhat similar to the Antonini 5116/L which I got for $14 some years ago, but probably isn’t that inexpensive today ![]()

I did see those and considered them. However, the steel they use is much softer than I prefer. Generally speaking, soft steels are easier to sharpen but require more frequent sharpening. I am capable of sharpening harder, more difficult steels, so I prefer one that will hold its edge longer.

Of course, softer steels tend to be tougher (less likely to chip or break). N690 doesn’t give too much up in that department, but it does lose some. The stainless Antonini uses (420) is more corrosion resistant, but not as hard or tough. Everything’s a tradeoff! Unless of course you pay through the nose for some of the super steels. Check out CPM MagnaCut steel-it’s pretty wild.

Remember, it doesn’t cost much to put fancy wood scales on a cheaper steel. You can get a knife that “looks” like this for $5 drop shipped from China, but I suspect you wouldn’t be very happy with it. Find a steel you like from a brand that knows how to work it and has good finish work, and pay accordingly.

Check this link out for more than you ever needed to know about knife steels:

Stainless steels comparison:

Carbon steels:

“Fancy” carbon steel:

K so I’m one who tends to fall down rabbit holes… Just did, learned more about steel composition than I ever wanted to ![]()

The one I own may not be as tough of steel as some, but is certainly good enough for my meager needs. After a hundred or so grafts, no sharpening or honing is really necessary I think.

Antonini says it has an HRC value of 54 to 56 for which I found:

HRC: PROPERTIES OF CUTTING TOOLS

52-54 HRC

These are very soft steels but relatively solid and inexpensive knives can be made out of it. Their sharpness is reasonable, yet not very smooth or fine. Due to the structure of these steels, they are not simple to sharpen with whetstones at home. Due to its better ductility, a knife with a lower HRC value bends rather than breaks if too much force is applied. It’s a better choice for outdoor knives.

54-56 HRC

Most French kitchen knives fall into this category. The steel is hard enough for kitchen knives, but they need to be regularly honed with a honing rod to maintain sharpness. They are easy to sharpen.

56-58 HRC

Professional German kitchen knives with this hardness value maintain good sharpness if regularly and often honed with a steel honing rod. They are easy to sharpen.

58-60 HRC

This hardness is typical of quality pocket knives, such as Spyderco, Cold Steel and Buck, as well as some Japanese kitchen knives like Global. These knives maintain sharpness for a substantially longer time. They are easy to sharpen.

60-64 HRC

Most world-class Japanese knives fall into this hardness span and they remain sharp for an incredibly long time. They require special care and work on a suitable surface to prevent breakage and damage to the blade. Due to their slight brittleness in combination with a thin blade, they are not suitable for any task. They must be handled gently and precisely. They are easy to sharpen.

65-68 HRC

Powdered steels: ZDP-189, HAP-40, R2, Super X etc.

In recent years, technological advancement spurred the creation of new types of steel that reach hardness as high as 64-68 HRC and boast mind-blowing properties. They are a little harder to resharpen. Knives carefully crafted from powdered steel are crème de la crème of kitchen tools.

I have 2 knives. The 1st one is for slicing and the 2nd one is for shaving.

Kershaw Rogue made in Japan. Small and thin. Stainless steel knife. Well balance and easy to control. Use for slicing such as cleft graft.

Off-Grid Knives RAPID FIRE RANGER made in Taiwan. Fancy Cryogenic D2 blade steel. Really sharp. Fairly large knife. Got some weight and good grip. Great for shaving and peeling corner of bark.

That’s the spirit! You’re absolutely right, the most important thing is if it meets your needs. The other tradeoff these steels have is cost. The ones that score highly on edge retention, toughness, and corrosion resistance also cost more to produce and require more expensive work to make the final product. I could get a grafting knife made out of one of those super steels at 64 hrc. While it would be magnificent, I suspect I’d be looking at a custom job and a $100-200 premium over the next best thing. Not to mention it would be like buying a Ferrari for grocery trips.

@smilemore Kershaw makes some nice knives for sure.

I also want to point out that the AM Leonard knife mentioned above is likely 14C28N from the stainless chart. AM Leonard doesn’t specify which of Sandvik’s steels it uses, but 14C28N is their flagship. So, that steel has very good toughness (not likely to chip), pretty good edge retention, and excellent corrosion resistance. I’m sure it would also be a great choice knife. I ended up with the Dui Buoi because it looks like it has a bit better of a fit and finish and because it explicitly says which steel they used and the hardness they finish at. Plus I’m a sucker for whatever isn’t the popular choice.

I think stainlessness is highly underrated by grafting knife afficionados. I get why, too: the earlier stainless steels weren’t so hot in terms of performance. Modern stainless is much better, though*. The thing with carbon steel is that even if you get it razor sharp, it can lose that edge just from forgetting to clean it in a timely manner and wipe it down with oil/WD-40, etc. If you can remember to do that every time, great. I know I’m pretty bad about it.

*Note that not all currently produced knives use the better, modern stainless. Be especially wary of stainless steels for grafting knives under $20. They’re probably using very soft steels and/or not heat treating properly.

Ditto for me as well.

Btw I used the Antonini Old Bear grafting knife for most of my grafts this year. Really enjoyed the locking mechanism and it was very sharp (sharper than i expected as I dont think i saw the chisel-ground as deep as you’d see on Victorinox/Felco-style knives ). I still really like the Victorinox/Felco-style grafting knives (spring is not as tight so doesn’t feel like its going to chop your finger off when folding it back in), but will try and use Old Bear as my #1.

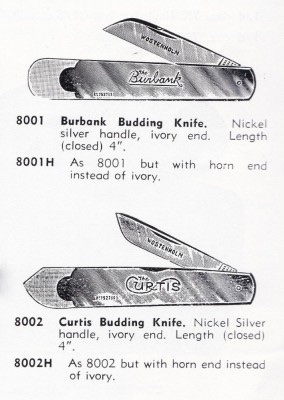

On a random note, these old vintage Luther Burbank and Charles Curtis grafting/budding knives are kinda fun vintage piece (can find them on etsy/ebay for around $60-$90). Im more familiar with Burbank so bought a couple this year as a collector piece (but maybe I’ll do a graft or 2 on it next year for fun).

Some pics…

"The George Wostenholm cutlery business goes back to the 18th century and the eponymous founder was born in 1775 and died in 1833. This Curtis budding knife was named after renowned botanist Charles Curtis and was made by the George Wostenholm factory. It is model 8002H and is made with a nickel silver handle and horn “spud” end-piece. The knife measures 4 inches closed. The face scale is stamped “The Curtis”. The clip point blade is an unusual shape for this model and is tang stamped “IXL George Wostenholm Sheffield England” on the face side and “Oil the Joints” on the reverse. "

“The George Wostenholm cutlery business goes back to the 18th century and the eponymous founder was born in 1775 and died in 1833. This Burbank budding knife was named after renowned botanist Luther Burbank and was made by the George Wostenholm factory. It is model 8001H and is made with a nickel silver handle and horn “spud” end-piece. The knife measures 4 inches closed. The face scale is stamped “The Burbank”. The blade is stamped “IXL” and is tang stamped “IXL George Wostenholm Sheffield England” on the face side and “Oil the Joints” on the reverse.”

Btw the Old Bear grafting knife now has a lossening/tighten mechanism on newer models maybe … i been using it as my main knife and decided to get another one.

i bought a old but unused soregen (probably misspelled) grafting knife off of guy on Ebay about 5 years ago. after a little touching up on my stones. i could shave with it and havent sharpened it since. dont know what steel it is but its pretty hard. thankfully it was pretty sharp al ready so it only touched it up a little on my fine grit stones. i have several others that are much easier to sharpen and work well but need to be resharpened every year. one was a old pocket knife my father in law gave me from the 60’ s which also has hard steel.

I have one of these, too. Love it. The lock mechanism has worked well for me this season, particularly with cleft grafts into larger limbs, it stays put instead of folding up like my old knife.